![]()

AutoMax Plus

![]()

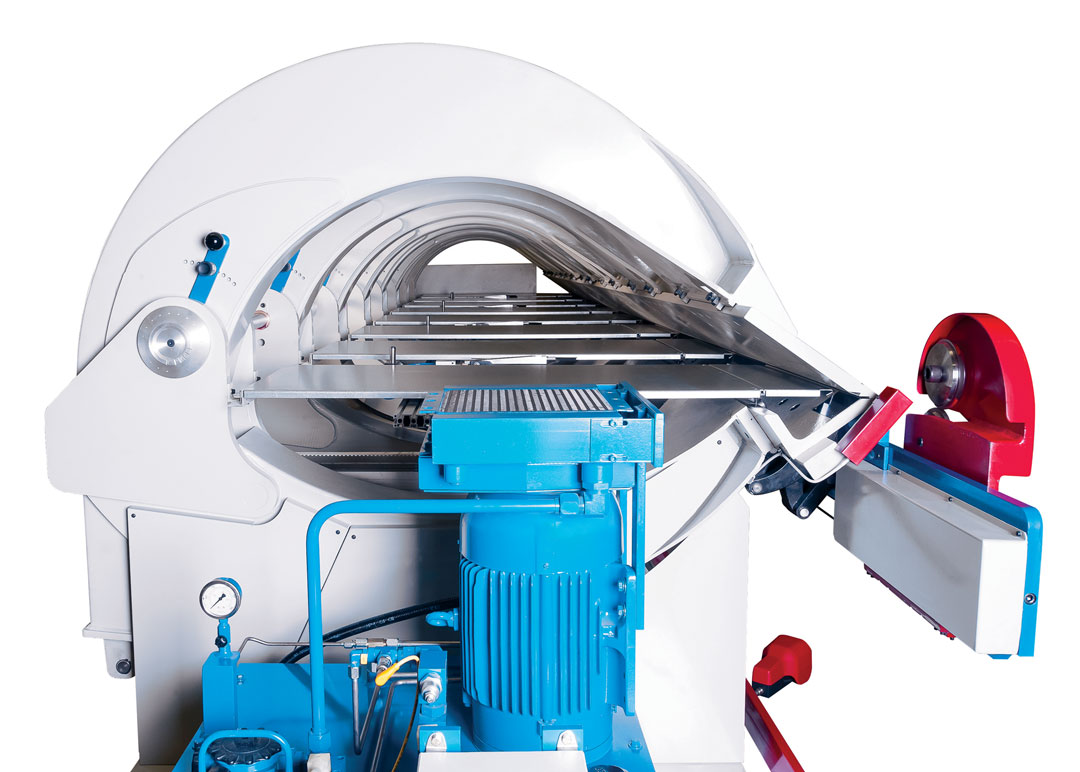

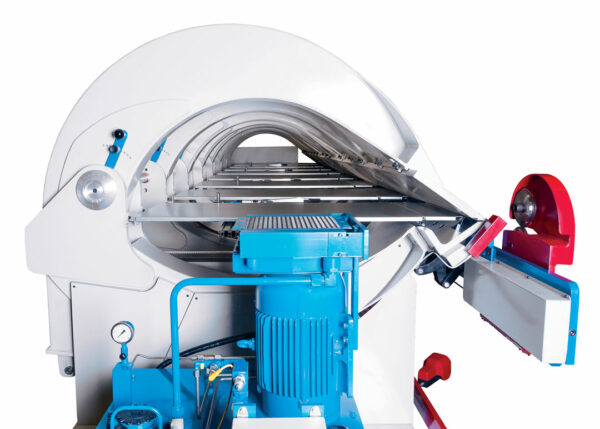

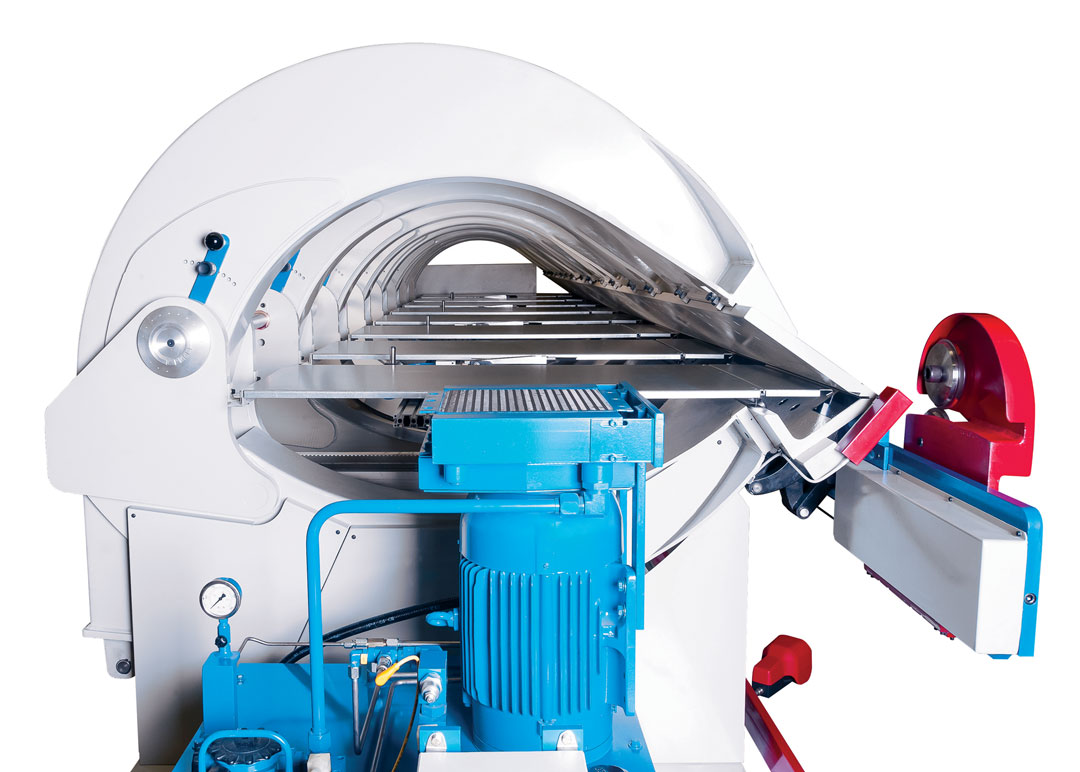

The AutoMax Plus offers all of the same features and functions of the standard AutoMax, in addition to providing increased capacity. With the most versatility, the AutoMax Plus bends material up to 14 gauge. This sheet metal brake has additional free space on the inside of the machines which allows for larger flanges to be put inside of the machine while forming the opposite side. The AutoMax Plus combines automated bending of angles up to 145 degrees, material clamping, and material support into a single CNC controlled system employing wing bending techniques.

The AutoMax Plus is a solid plate and weldment designed machine, delivering superior performance and features. The unique round design of the C frame gives this machine an extremely rigid foundation. The AutoMax Plus AMP2114 has eight C frames where competitive machines only have five. The additional frames improve hemming performance while reducing stress of the part giving the most consistent bends possible.

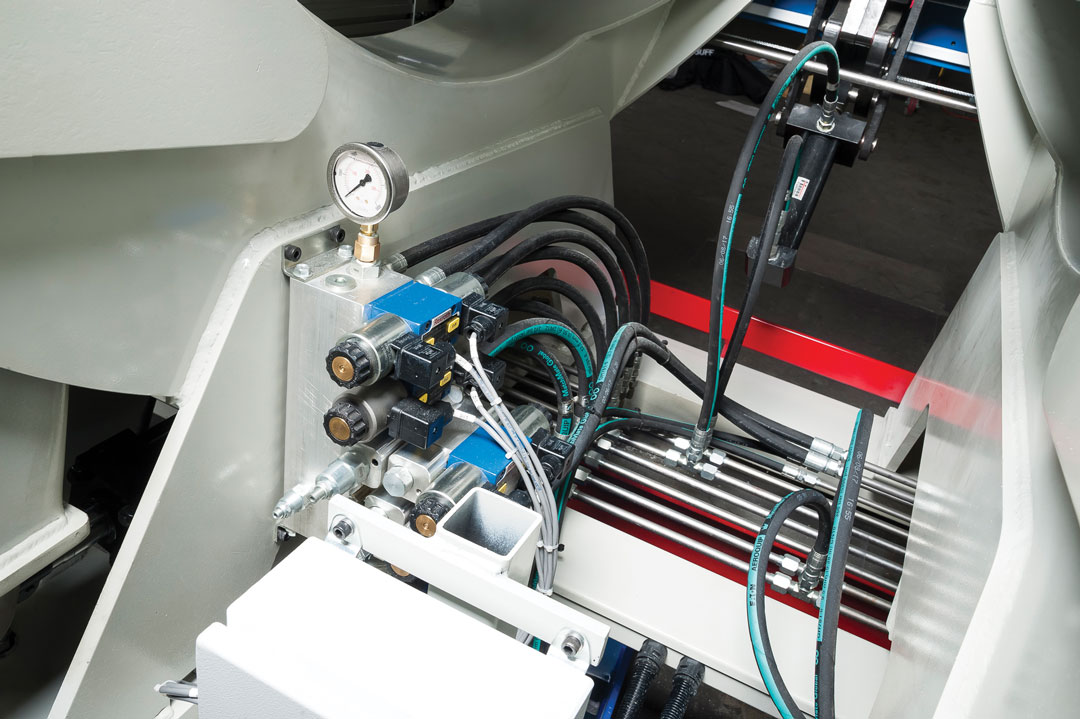

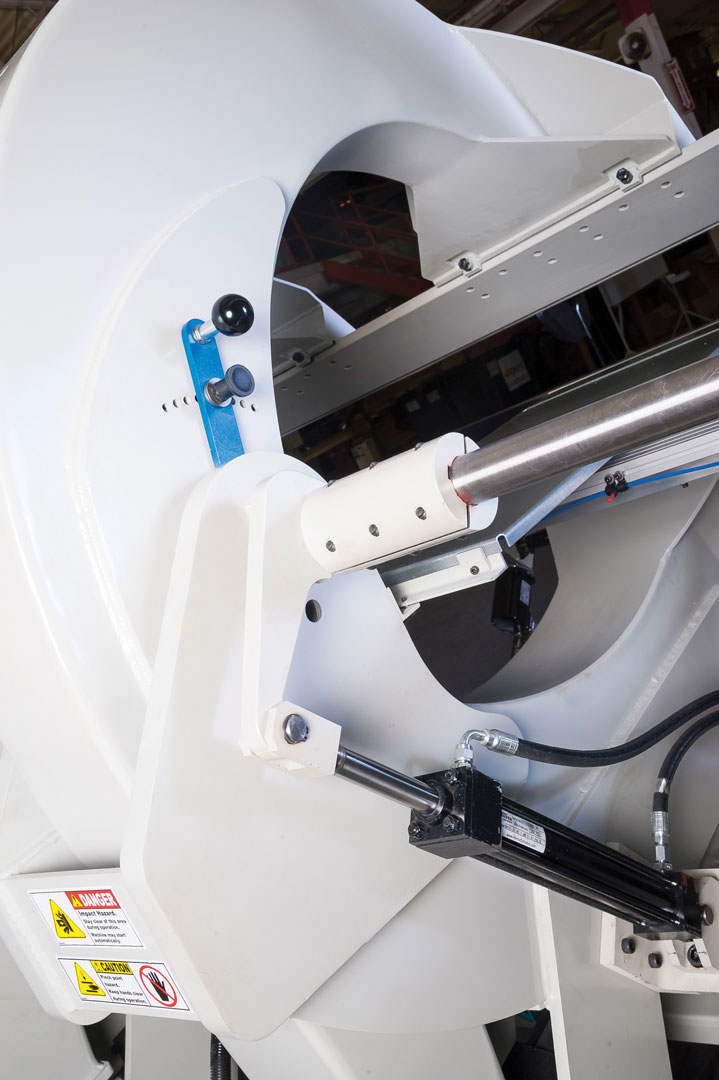

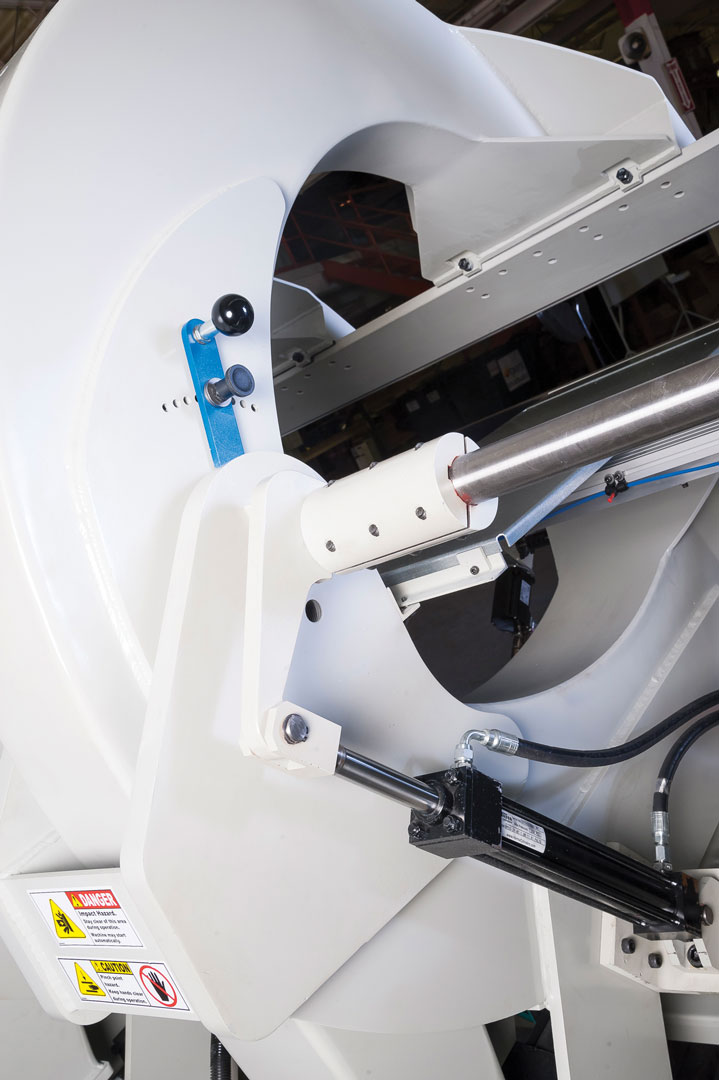

The hydraulic unit is located at the left side of the machine for easy routine maintenance access. The hydraulic manifold is located at the center of the machine, which allows for even flow of hydraulic pressures, giving the machine smooth even operation. The bending leaf is powered by three cylinders. The system is equipped with a hydraulic fluid cooling radiator as standard.The electrical cabinet is located at the right side of the machine in a quick lock enclosure along with the Synergy control.

The curved C Frame design provides superior clamping pressures while eliminating stress points seen on competitive machines. This design allows for much more free space for complicated bends / profiles. The maximum opening height of the AMP2114 is 9.5.

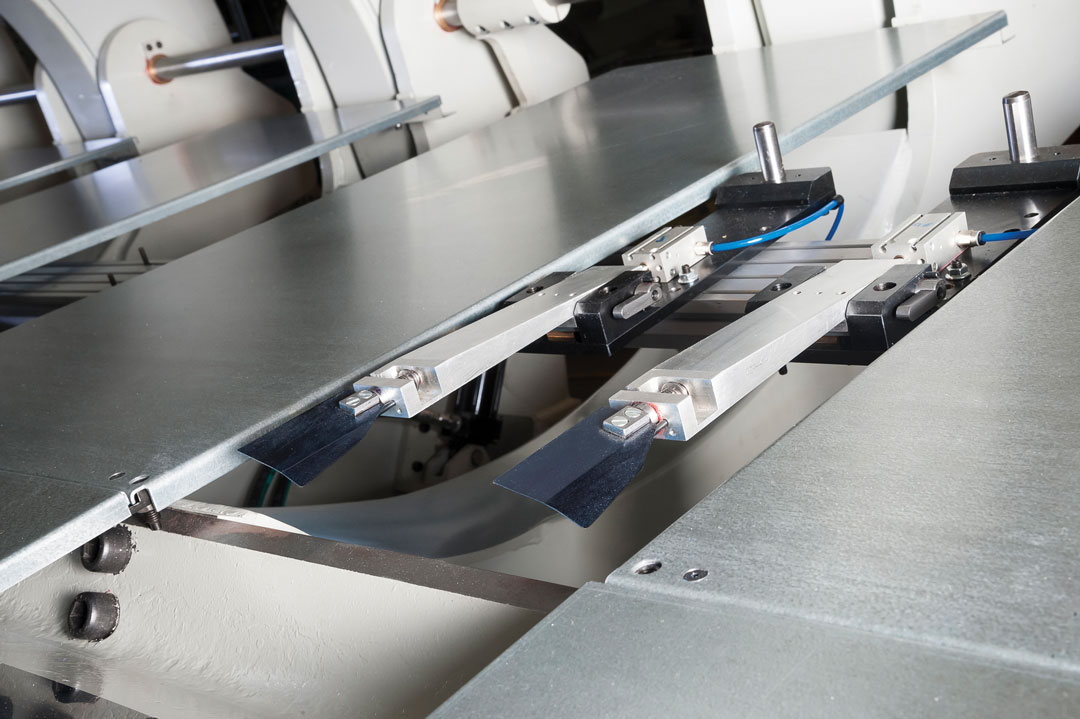

Work pieces are fully supported by the back gauge tables beneath the clamping C frames, and automatically positioned to an accuracy of +/- .004″. The back gauge is positioned by a servo motor for low noise operation.

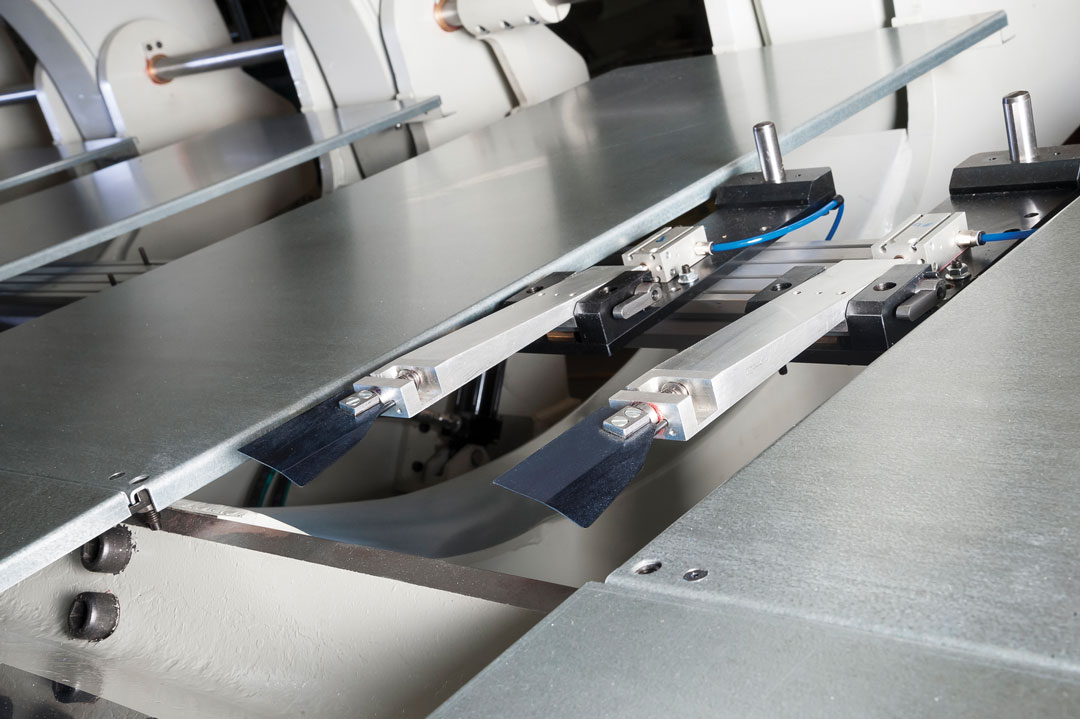

Five conveniently spaced fingers provide positive contact with the sheet edge at all times and the fingers will travel down to 0.394 position. The AutoMax comes standard with a small parts back gauge finger set. The small parts back gauge allows the operator to run smaller parts than are normally able to be made on long folding machines. Parts down to 4 are possible. Maximum back gauge travel can be reached in less than 3 seconds. The standard back gauge depth is 49.

Crowning is also standard on the AutoMax long folding machines. Each C frame has an adjustment dial that allows the operator to adjust the angle of bend at different points along the machine.

The Slitter for the AutoMax is mounted to the lower frame of the machine, freeing the folding beam of any obstructions. The slitter is hydraulic powered via frequency invertor. The unit is guided by two precision ground linear rails. The rigid mount of the AutoMax Slitting unit allows quick and accurate cutting of material at capacity.

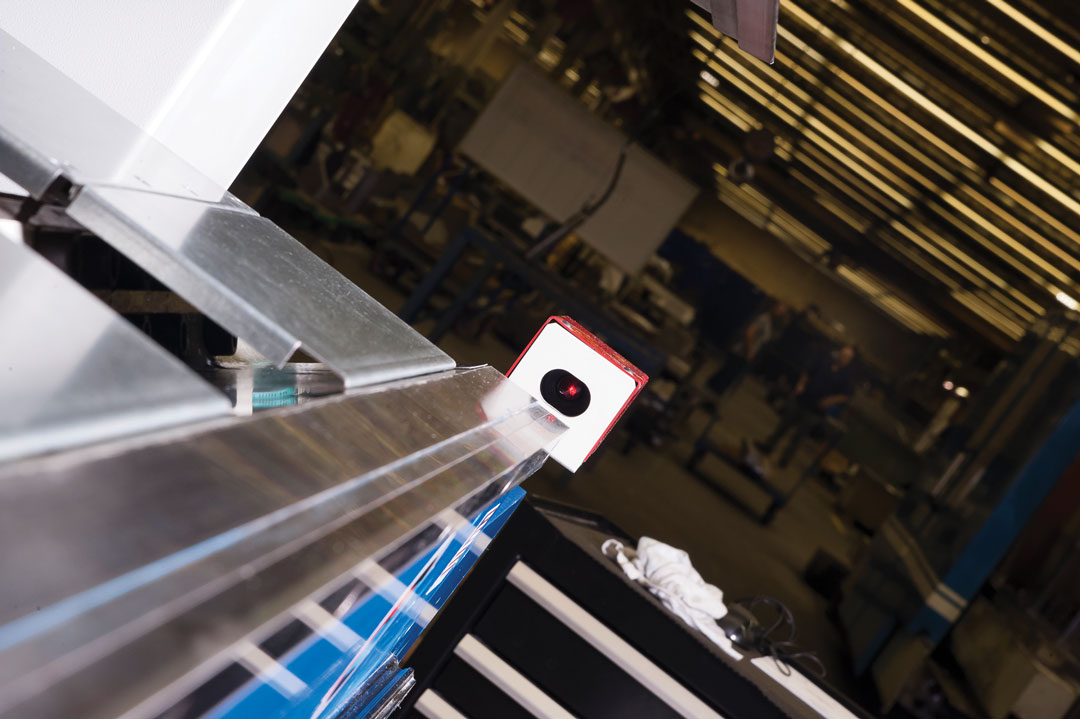

- Laser Guarded Pinch Point

- Safety Bar

- Emergency Stop

- Clamping Beam Closure Safety

- Closing Speed Slow Down

- Second Man Pedal

| Bending Length | 21.3' / 6.5 m |

|---|---|

| Maximum Bending Capacity Mild Steel | 14 ga / 2.0 mm |

| Maximum Bending Capacity Stainless Steel | 16 ga / 1,6 mm |

| Maximum Bending Capacity Aluminum | 1/8 in / 3,0 mm |

| Maximum Slitting Capacity Mild Steel | 14 ga/ 2.0 mm |

| Back Gauge Travel | 49 in / 1250 mm |

| Number of Back Gauge Fingers (Standard) | 5 |

| Minimum Back Gauge Distance (Gripping) | 0.787 in / 20 mm |

| Minimum Back Gauge Distance (Pushing) | 0.394 in / 10 mm |

| Number of C Frames | 8 |

| Number of Bending Cylinders | 3 |

| Width of Folding Beam | 0.394 in / 10 mm 1 in / 25 mm with reinforcement bar |

| Folding Beam Maximum Bend | 145 degrees |

| Standard Clamping Rail | 35 degrees |

| Slitter Offset from Bending Point | 2.5 in / 70 mm |

| Hydraulic Motor | 10 HP |

| Pneumatic Supply | 6 bar / 1 CFM |