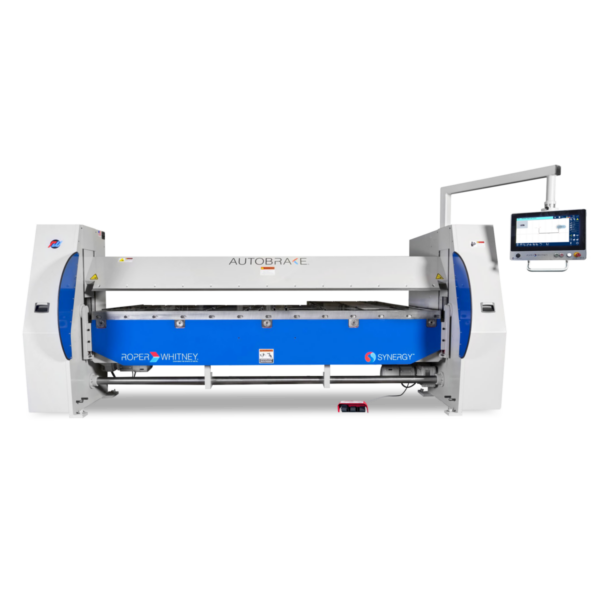

The all-new design of the 1016 Autobrakes upper jaw goes from a 30 angle to a tighter 20 angle, increasing the folding beam arc from 146 to 156. This means less clamping pressure is needed when closing a hem, giving you a straighter, more compressed hem in less time.

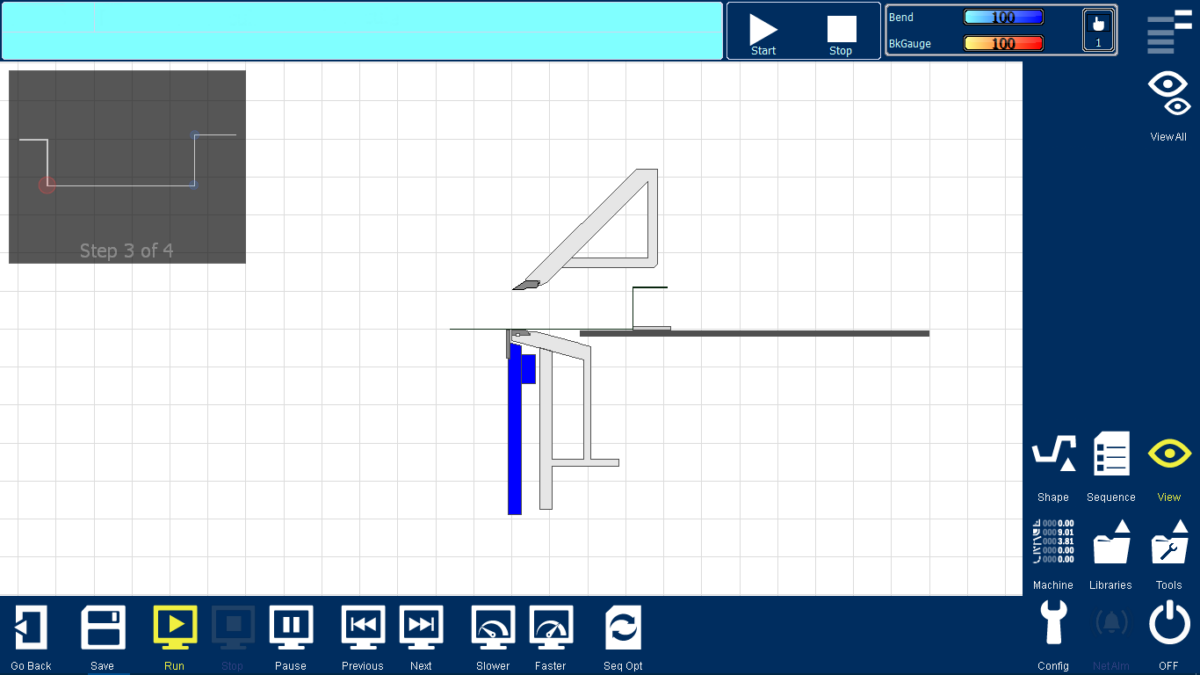

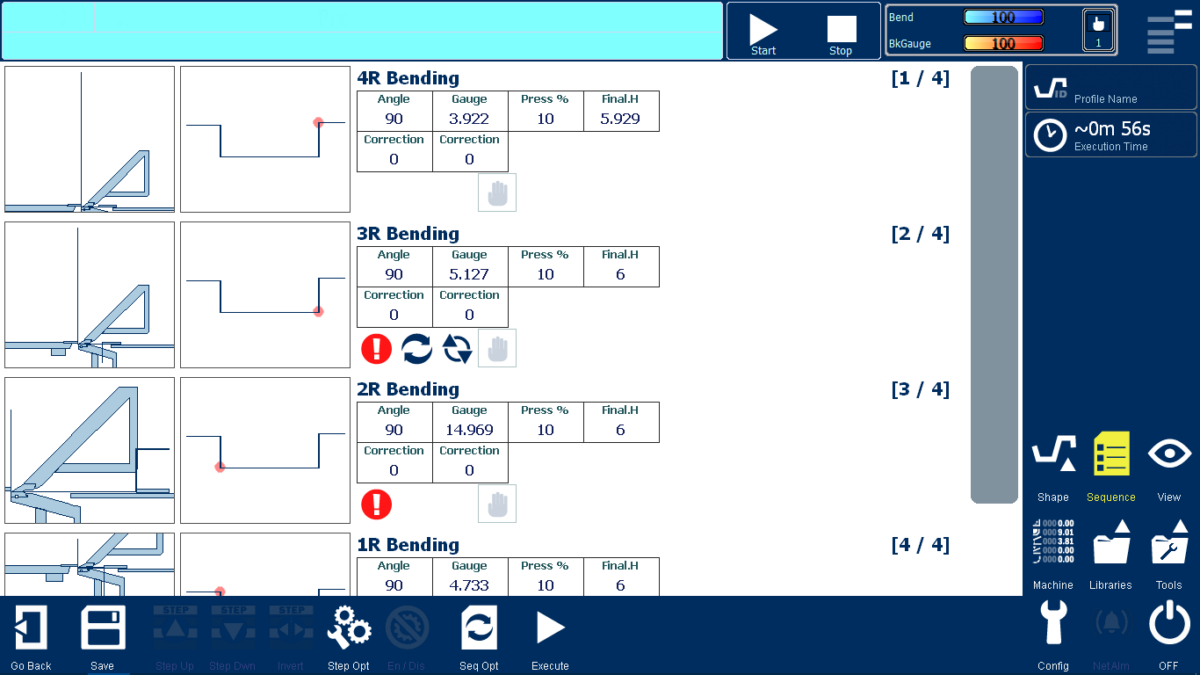

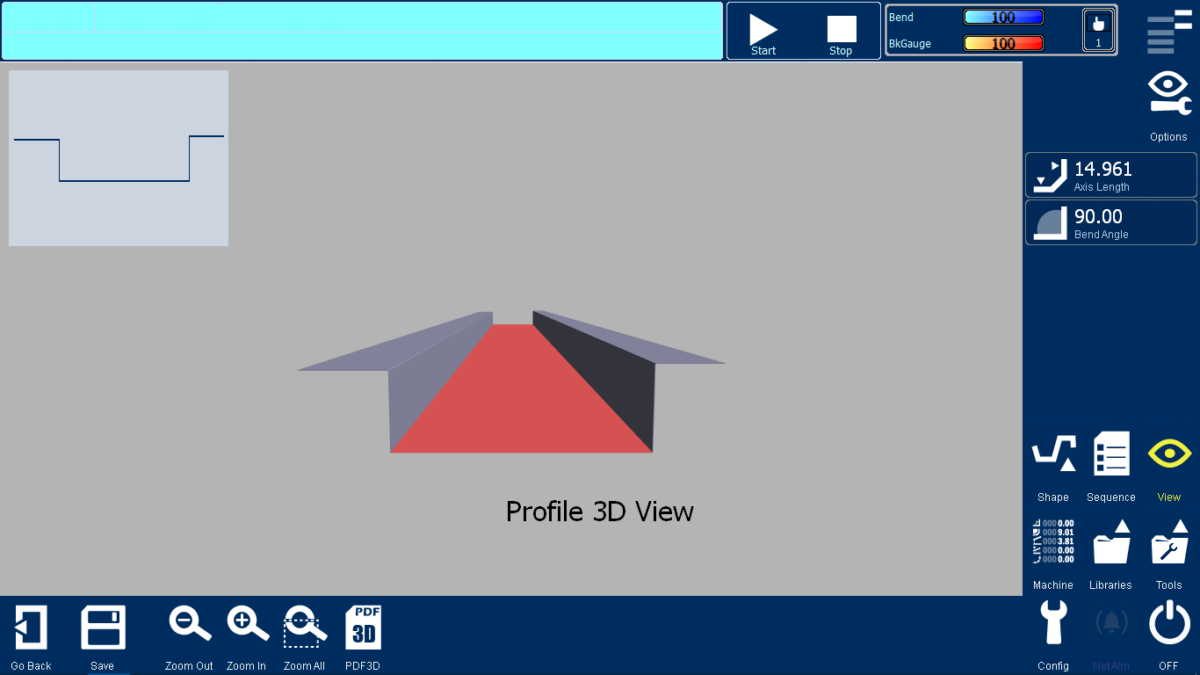

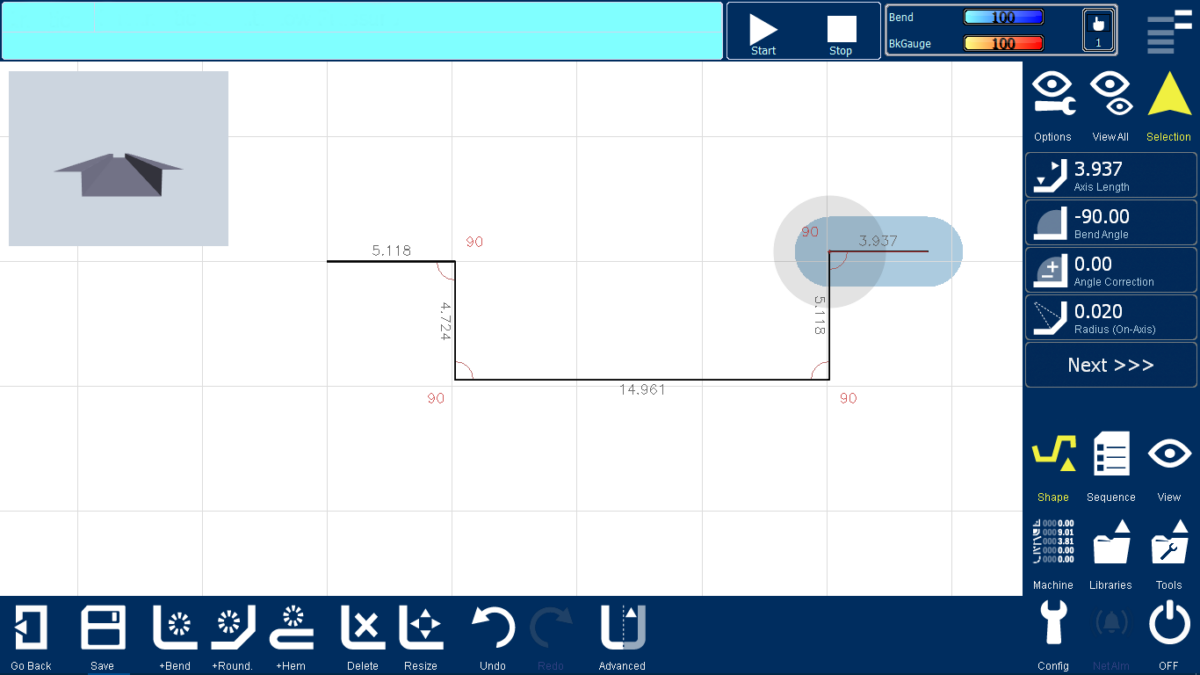

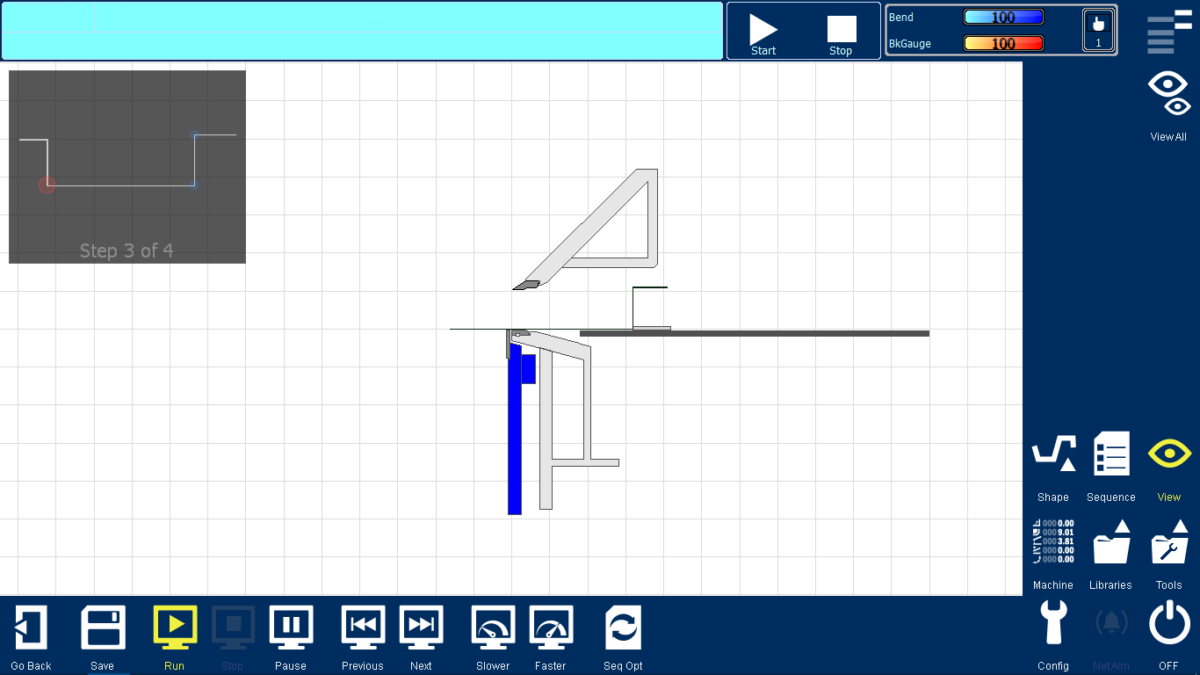

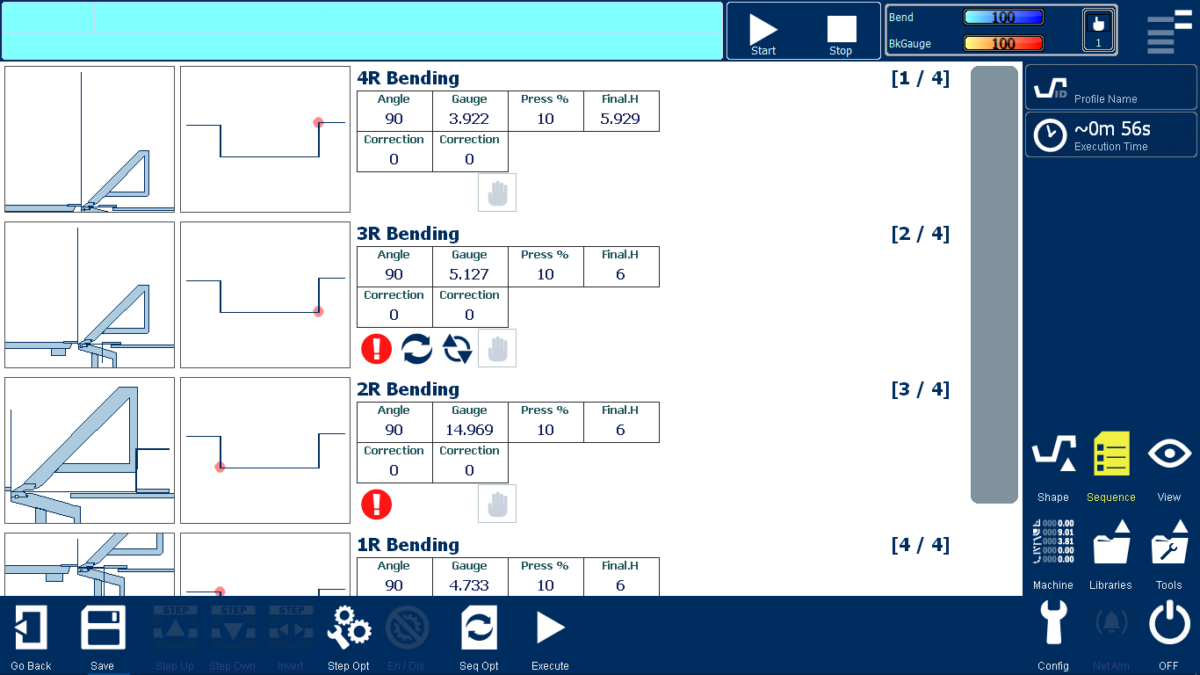

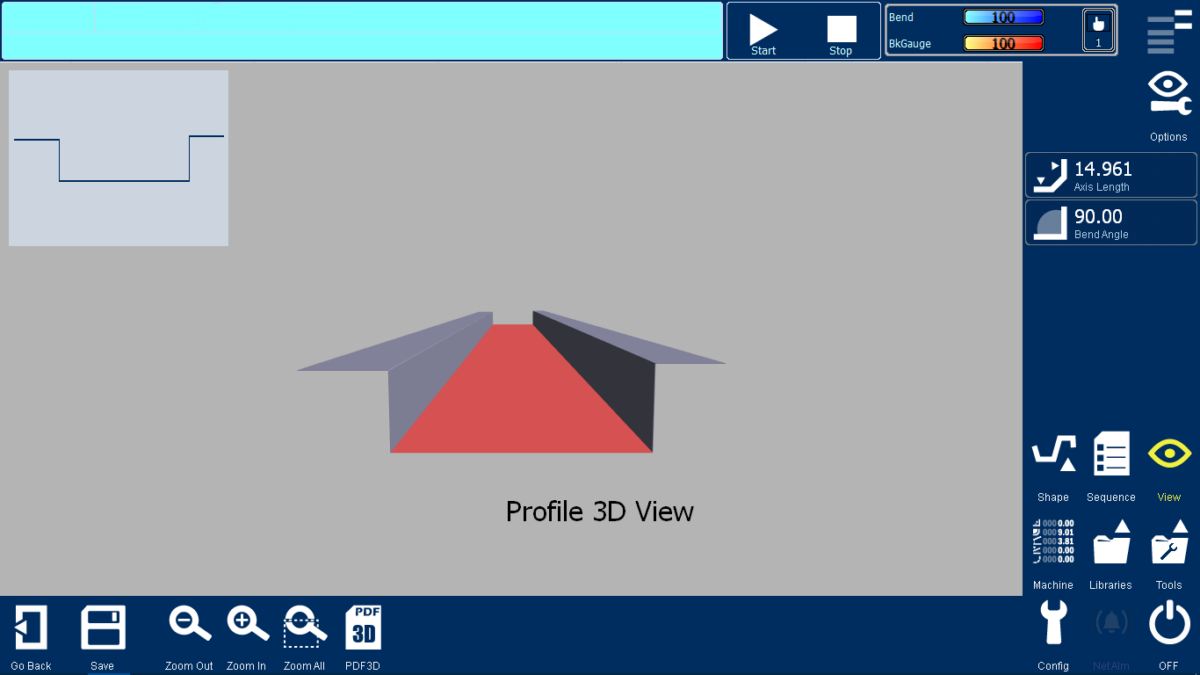

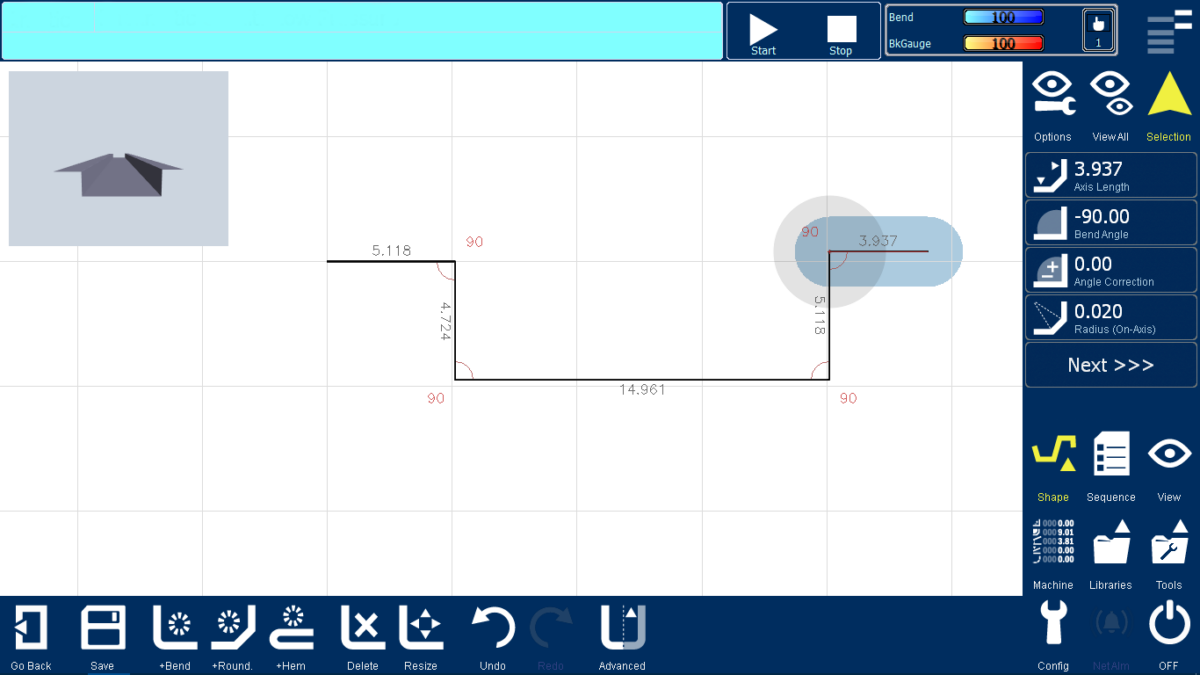

The Synergy control offers high speed versatility to an end user. It offers multiple methods of programming from simple line-by-line to draw-to-auto program. Its network capabilities allow for multiple options, such as; Konnect, Konstruct, Mobile Konstruct, and overall shop management through linking multiple machines. See more information on the Synergy Software by Roper Whitney.

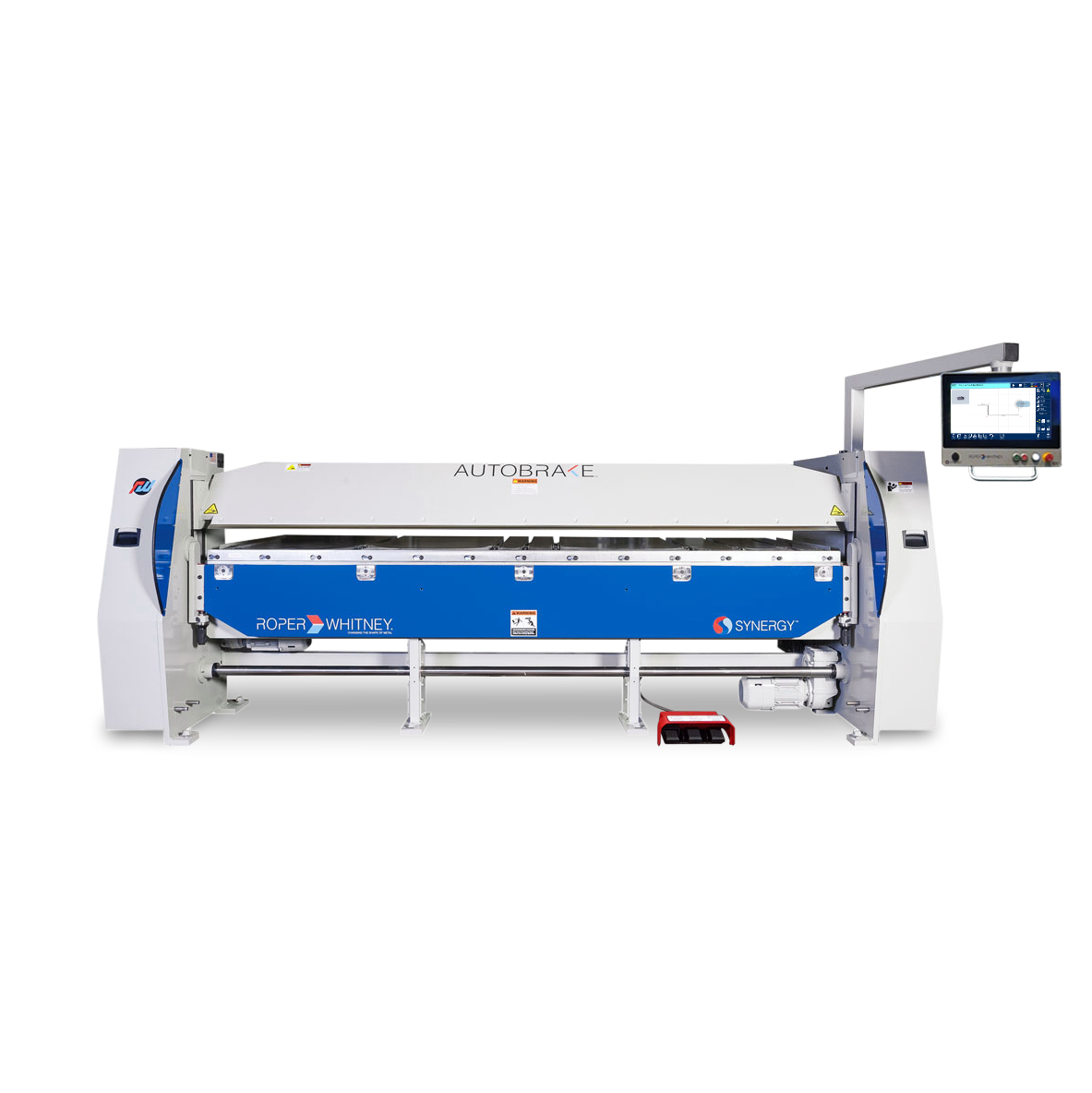

The Autobrake design is a plate and weldment steel construction, delivering superior performance and features in a simplified rigid design. End housings are a plate-type construction bringing drive components close together for improved stiffness and performance. Actuating mechanisms are secured in rigid mounts at the outside of the housings, allowing easy maintenance.

Clamping and hemming capabilities come standard and are already included in the software. Clamping and hemming power is delivered to the clamp jaws by a series of spring washers to provide variable clamping pressures with a shock-absorbing end stop. This provides reliable clamping pressure to create open, tear drop, and closed hems to best suit your needs.