Enhancing Sign Manufacturing with Speed, Precision, and Quality

In the dynamic world of sign manufacturing, which ranges from simple indoor safety signs to eye-catching large-format outdoor displays, speed and precision are crucial. Roper Whitney delivers versatile, reliable, and cost-effective sheet metal machinery, all proudly made in the USA, to boost your signage production and competitive edge.

Roper Whitney’s dedication to offering advanced sheet metal machinery for the sign manufacturing industry allows you to achieve the speed and precision necessary to thrive in a competitive market. By choosing our American-made machines, you can elevate your signage production and outshine your competitors.

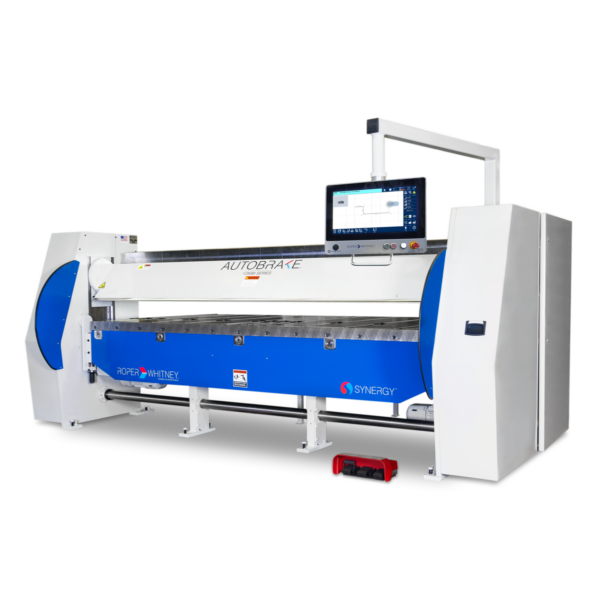

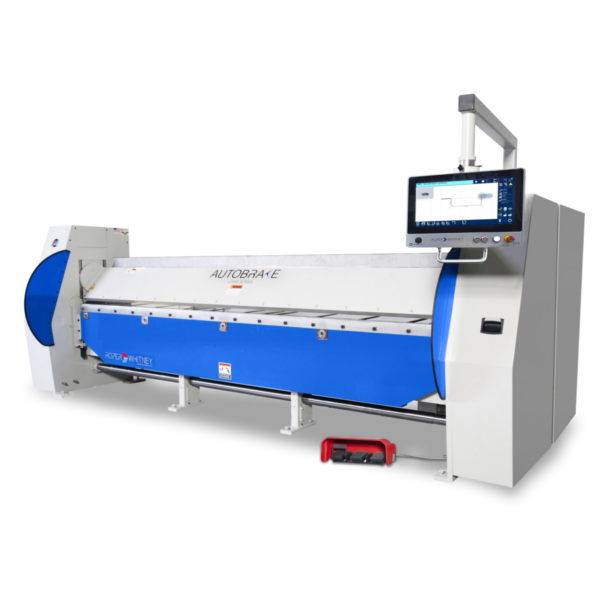

Autobrake Kombi Series

The unique Kombi box tooling adds to the machine’s straight and box folding capabilities, enabling the production of more complex shapes in less time. Various tooling options are provided to help customize to your specific needs, available in steel or hardened tooling. The Kombi Series handles a wide range of materials, easily closes hems, and withstands the force generated by maximum capacity. All of this is complemented by our user-friendly Synergy software.

Mechanical and Hydraulic Shears

These shears deliver accurate cutting capabilities for various sheet metal thicknesses, ensuring clean and precise cuts every time.

Featured Machines

10M14 Mechanical Sheet Metal Shear

The 10M14 capacity is 14 gauge mild steel, 18 gauge stainless steel and can shear material up to 121.25 inches in cutting length. The electro-mechanical design of the 10M14 provides quiet operation with low power consumption. The shear is initiated by a moveable foot switch. An oversized shield and toe kick plate are incorporated into the foot switch for added operator safety. The 10M14 is capable of 35 cutting strokes per minute.

911 Radius Master w/ 11 Radii, 1/8″ – 1″

$8,800 + Freight

Roper Whitney’s Radius Master is a must for every fabricating shop. It’s a hydraulically operated, self contained unit for making radii in mild steel from 27 gauge up to 7 gauge without having to make blade adjustments and no setup. The Radius Master comes standard with 11 radii from 1/8″ to 1″ – 1/8, 3/16, 1/4, 5/16, 3/8, 7/16, 1/2, 5/8, 3/4, 7/8, & 1″. Special size radii may also be ordered up to 3″ maximum radii. Specifications: Operated on 115 volts 1.0 amp and 80 psi shop air with safety foot switch as standard equipment.

AutoKut 160

The heavy-duty AutoKut 160 is ideal for customers seeking increased slitting and blanking capacity in a compact machine. The AutoKut 160 features automatically-controlled slitting shaft adjustments, straightening rollers, and feed rollers, streamlining processing. It is designed for long-term serviceability with all mechanisms outside the machine and does not require disassembly for blade changes. The 160 accommodates coils up to 49.25″ wide and can slit up to 16 gauge mild steel and blank up to 14 gauge. It comes standard with 5 pairs of easily-repositioned slitting blades and offers an approximate 1-second shear cycle time.

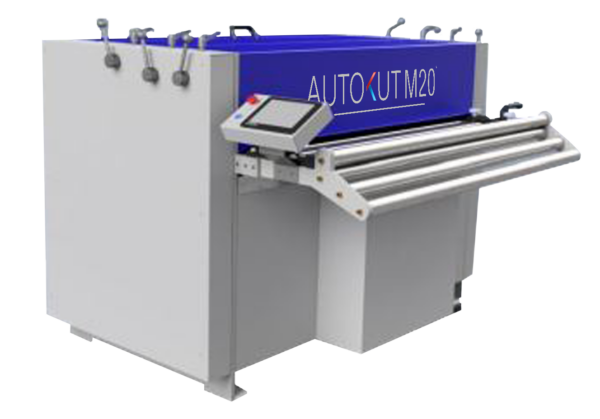

AutoKut M20

The AutoKut M20’s compact design takes up little space, ideal for smaller sheet metal shops. Its reliable feed system is equipped with ball-bearing side guides and a combination of adiprene-coated and steel rollers, ensuring smooth plate handling and reaching a feed rate of 65 feet per minute. The AutoKut M20 blanks and slits up to 20 gauge steel and accommodates coil widths of up to 49.25 inches. It includes a touchscreen Schneider control system, three straightening rollers, and slitting rollers that come standard with 5 pairs of knives.