Streamlining Industrial Fabrication with American-Made Solutions

As heavy equipment and industrial fabrication machinery grow more complex, the demand for increased customization and sophisticated software controls intensifies. Industrial fabricators must rise to the challenge of providing efficient, cost-effective manufacturing solutions in an increasingly competitive market. To succeed, they need to innovate and manage complexity for high-volume operations.

Roper Whitney’s dedication to providing industrial fabricators with innovative, American-made machinery simplifies complex processes while maintaining quality and efficiency. Our line of industrial fabrication machinery ensures that you can create the right product and do so with excellence, positioning you for success in today’s competitive market.

Comprehensive Industrial Fabrication Machinery Line

Roper Whitney provides an extensive range of industrial fabrication machinery for part manufacturing, including:

Autobrakes

Our patented, USA-made CNC folder. These computer numerically controlled (CNC) metal folders enable precise folding operations, enhancing productivity and efficiency.

PX Series Shears

These shears deliver accurate cutting capabilities for various sheet metal thicknesses, ensuring clean and precise cuts every time.

Autokut

Our cut-to-length systems facilitate efficient sheet metal processing, allowing customers to optimize material usage and minimize waste.

Synergy Software

Roper Whitney’s Synergy software for CNC folders is a user-friendly solution that sets them apart in the market by optimizing job tracking and production management. The software empowers customers to effectively handle orders, keep an eye on inventory, and schedule production tasks with ease. Users have praised the simplicity of the interface, stating that it makes Roper Whitney’s machines superior to those of their competitors.

Featured Machines

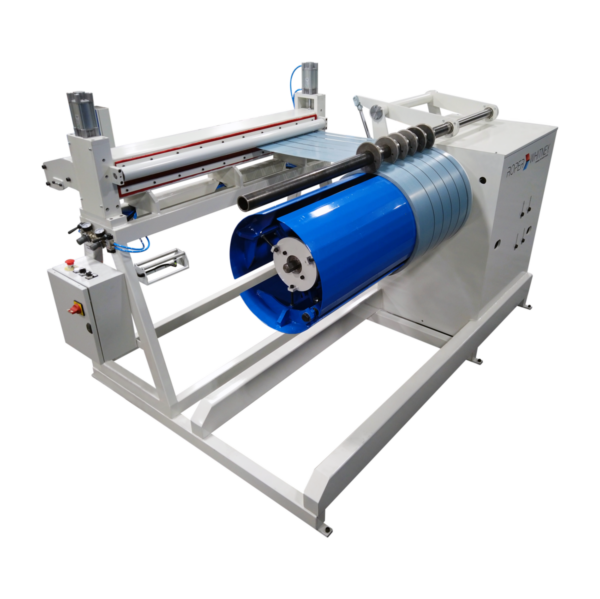

AutoKut 160

The heavy-duty AutoKut 160 is ideal for customers seeking increased slitting and blanking capacity in a compact machine. The AutoKut 160 features automatically-controlled slitting shaft adjustments, straightening rollers, and feed rollers, streamlining processing. It is designed for long-term serviceability with all mechanisms outside the machine and does not require disassembly for blade changes. The 160 accommodates coils up to 49.25″ wide and can slit up to 16 gauge mild steel and blank up to 14 gauge. It comes standard with 5 pairs of easily-repositioned slitting blades and offers an approximate 1-second shear cycle time.