Your One-Stop Partner for Architectural Metal and Roofing Solutions

If you are a professional in the metal roofing, siding, and trim industries, staying up-to-date with the latest trends and technologies is crucial. Roper Whitney is the go-to partner for both commercial and residential applications in the architectural metal and roofing sectors. By incorporating innovative technology and unique processing concepts, we empower our customers to overcome the challenges of architectural metal fabrication.

Roper Whitney is the trusted partner for professionals in the architectural metal and roofing industry. Our comprehensive range of machinery and software solutions allows you to stay ahead of the curve, meeting the demands of complex and precise metal fabrication tasks. By choosing Roper Whitney, you can be confident in delivering high-quality products and services to your clients, every time.

Our Complete Line of Metal Fabricating Solutions

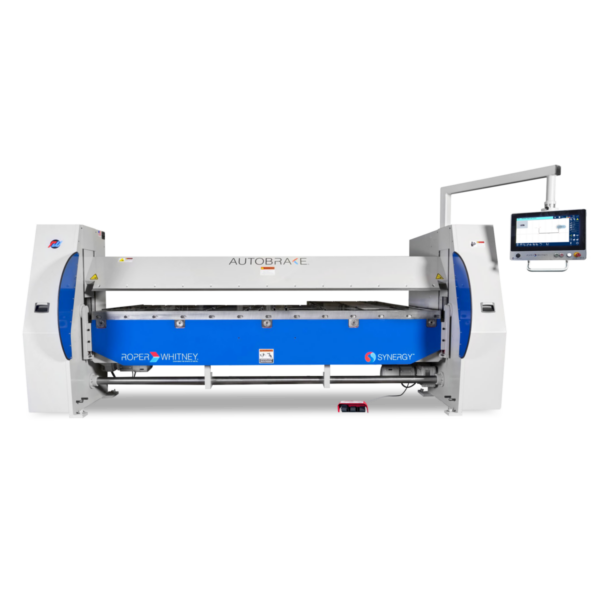

Autobrakes

American-made precision metal folders with Synergy software for enhanced usability and control.

Automax

Long folders for handling large sheet metal panels in roofing and siding applications.

Mechanical Shears

Our mechanical shears offer precision cutting capabilities for various sheet metal thicknesses, ensuring clean and accurate cuts every time.

Decoilers, Recoilers & Coil Processing Machines

Streamline sheet metal processing for optimized material usage, minimized waste, and proper storage and transportation of finished products.

Trim and Custom Profile Roll Forming Machines

Expanded options through partnership with Roll Former LLC for architectural trim, custom profiles, and standing seam panels. Additionally, their portable standing seam rollformers allow for on-site fabrication of metal roofing panels, increasing flexibility and shortening lead times.

Synergy Software

Roper Whitney’s Synergy software for CNC folders is a user-friendly solution that sets them apart in the market by optimizing job tracking and production management. Users have praised the simplicity of the interface, stating that it makes Roper Whitney’s machines superior to those of their competitors.

Featured Machines

10M14 Mechanical Sheet Metal Shear

The 10M14 capacity is 14 gauge mild steel, 18 gauge stainless steel and can shear material up to 121.25 inches in cutting length. The electro-mechanical design of the 10M14 provides quiet operation with low power consumption. The shear is initiated by a moveable foot switch. An oversized shield and toe kick plate are incorporated into the foot switch for added operator safety. The 10M14 is capable of 35 cutting strokes per minute.

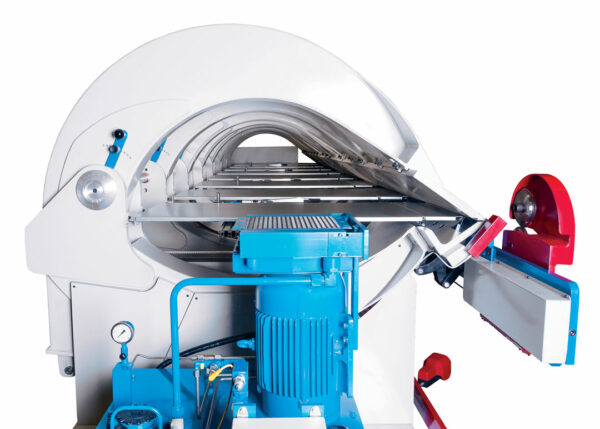

AutoKut 160

The heavy-duty AutoKut 160 is ideal for customers seeking increased slitting and blanking capacity in a compact machine. The AutoKut 160 features automatically-controlled slitting shaft adjustments, straightening rollers, and feed rollers, streamlining processing. It is designed for long-term serviceability with all mechanisms outside the machine and does not require disassembly for blade changes. The 160 accommodates coils up to 49.25″ wide and can slit up to 16 gauge mild steel and blank up to 14 gauge. It comes standard with 5 pairs of easily-repositioned slitting blades and offers an approximate 1-second shear cycle time.

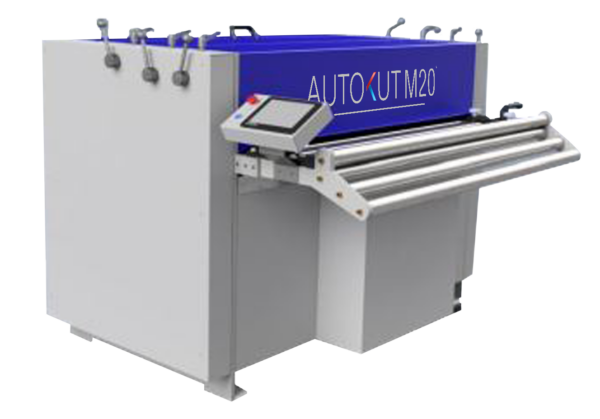

AutoKut M20

The AutoKut M20’s compact design takes up little space, ideal for smaller sheet metal shops. Its reliable feed system is equipped with ball-bearing side guides and a combination of adiprene-coated and steel rollers, ensuring smooth plate handling and reaching a feed rate of 65 feet per minute. The AutoKut M20 blanks and slits up to 20 gauge steel and accommodates coil widths of up to 49.25 inches. It includes a touchscreen Schneider control system, three straightening rollers, and slitting rollers that come standard with 5 pairs of knives.

AutoMax

![]()

With the creation of the Automax folding machine, we have set ourselves apart from the competition. This new model has the most free space in the industry allowing the operator to create shapes that cannot be created on competitors machines. The extra free space also reduces part handling which is important on long pieces that are difficult to manipulate.

AutoMax Plus

![]()

The AutoMax Plus offers all of the same features and functions of the standard AutoMax, in addition to providing increased capacity. With the most versatility, the AutoMax Plus bends material up to 14 gauge. This sheet metal brake has additional free space on the inside of the machines which allows for larger flanges to be put inside of the machine while forming the opposite side. The AutoMax Plus combines automated bending of angles up to 145 degrees, material clamping, and material support into a single CNC controlled system employing wing bending techniques.