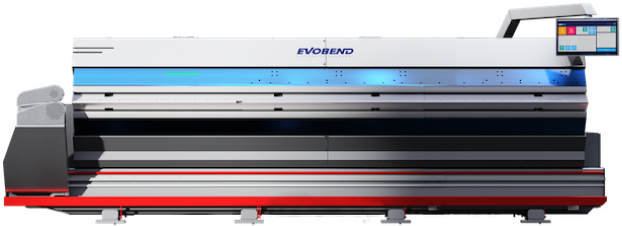

INTRODUCING THE NEXT GENERATION OF UP/DOWN FOLDERS

Evobend® – The next generation of folding technology and innovation. Developed over the course of several years, our work is guaranteed by our unrivaled quality and flexibility in bending. In addition to the most energy efficient machines on the market, the Evobend® also ensures your safety with the help of our servo-electric safety fence technology. Discover this and the many more advantages of the revolutionary Evobend®.

Unrivaled Flexibility

The Evobend’s patented double bending system has been refined in a revolutionary way and enables unmatched bending freedom. Due to the Evobends innovative design, previously impossible angles are now able to be processed. Up to 300° (150° up, 150° down) of bending freedom is unrivaled anywhere else on the market. This increases your flexibility when folding parts and allows for more demanding profiles to be produced at a lower cost.

The virtually scratch-free bending technology of the Evobend provides additional aesthetic value. Until now, bending beams have folded sheets through swivel movements. However, this can permanently damage your sheet metal parts, the “rubbing” of the bending tools on the sheet metal is now a thing of the past! By rolling the bending tools based on your bending curves, minimal marking is left on your work piece.

» 300° bending clearance (150° up, 150° down) for more demanding profiles

» Minimal wear on parts

» Time and cost savings

» Increased flexibility

Less Energy Consumption

The Evobend’s efficiency is achieved in three primary ways:

- Traditional bending beams are generally equipped with regular bearings – the Evobend, however, is completely ball bearing mounted. The friction coefficient of regular bearings to ball bearing is 1:10, therefore the Evobend prevents energy loss caused by heat generation.

- Current long folding machines on the market today are all hydraulically operated. The efficiency of a hydraulic system is about 50 %. This means that half of the supplied energy is directly converted into heat. Evobend prevents this energy loss by operating completely hydraulic free and achieving an efficiency rating of 98% with our electric drives.

- The energy consumption during the bending process is also greatly reduced via the new control unit in combination with special bending tools. With the Evobend you save electricity and money all while working in an environmentally friendly and sustainable way.

» Fully electric, no hydraulics

» Reduced heat and friction build-up from ball bearings

» Environmentally friendly and sustainable

Improved Safety

From the very beginning, Evobend made sure that their machine was designed to be as safe as possible. Every folding machine user knows the innumerable requirements that arise when purchasing a new machine. Therefore, operator safety is a top priority. This is achieved by fully enclosing the machine, which prevents shearing and crushing hazards.

In addition, the Evobend’s electrically driven safety fences extend while in operation to ensure increased safety for the operator. Once completed, the fences retract to their resting position and therefore don’t take any unnecessary space.

» Fully enclosed machine

» No swinging out of bending beam

» No risk of a hydraulic accidents

» Innovative safety fence technology

Compact Design

By taking spatial planning into account early in Evobend’s developmental stages, we are able to achieve significant space advantages. Compared to traditional long folding bending machines, the Evobend requires considerably less space.

Regularly rising facility expenses are a decisive factor nowadays. The Evobend takes up 30% less space than traditional machines and is optimal for shops with limited space conditions.

» Smaller overall size than traditional folders

» 30 % less space consumption

» Retractable safety fences

» Optimal for limited space conditions

Reduced Maintenance

The bearings in traditional folding machines are susceptible to high wear due to regular bearings commonly used in the industry. In addition, every hydraulic system requires regular maintenance, not to mention annual replacement of various hydraulic hoses. Oil puddles occur quickly, and a costly visit from a service technician is usually the result. Evobend prevents these problems with an all new type of ball bearing. Completely free of hydraulics, the typical problems are a thing of the past.

Thanks to the Evobend’s 4.0 remote capabilities, any setting changes required are possible at any time, and not by way of an expensive service visit – but rather a simple click of a mouse. The machine automatically recognizes the need for preventive measures after continuous operation. When used properly, the Evobend works wear-free, so that no readjusting is necessary.

» Fewer installed parts than a traditional machine

» 4.0 remote troubleshooting and maintenance

» Update your settings at any time

» Hydraulic-free, drastic reduction of hoses, oil, etc.

Uncompromised Innovation

The Evobend was developed over the course of several years by incorporating customers’ needs and wishes into the construction of the machine.

The Evobend is not just a face-lift or a further enhancement to a traditional long-folding machine, but rather the next generation of folding machines in the marketplace. Evobend is the next generation of folding technology and innovation.

» Patented bending technology

» Reduced noise pollution ensures more comfortable working conditions

» Use of the latest linear technology with all its advantages (energy consumption, volume)

» Contemporary 4.0 concept

Models Available

Model D300

The 10 ft. version is the smallest of the Evobend® models. Where space is limited, its compact design allows you to work comfortably while other machines reach their limits. The D300 is also a perfect solution for operators who commonly bend smaller profiles.

Specifications:

» Folding Length: 126 in (3200 mm)

» Backgauge Depth: 49 in (1250 mm)

» Number of Legs: 4

» Total Length: 181 in (4600 mm)

» Total Depth: 71 in (1880 mm)

» Total Height: 74 in (1875 mm)

» Max. Capacity Mild Steel: 14 ga (2 mm)

» Max. Capacity Aluminum: 1/8 in (3 mm)

» Max. Capacity Stainless Steel: 18 ga (1.25 mm)

Model D400

The 15.5 ft. version Evobend®

With this machine you will work faster and more efficiently than with comparable machines. Metal building contractors, roofers, facade builders and many other sheet metal fabricators look forward to a long-folding machine of this exceptional quality.

Specifications:

» Folding Length: 187 in (4746 mm)

» Backgauge Depth: 49 in (1250 mm)

» Number of Legs: 6

» Total Depth: 71 in (1880 mm)

» Total Height: 74 in (1875 mm)

» Max. Capacity Mild Steel: 14 ga (2 mm)

» Max. Capacity Aluminum: 1/8 in (3 mm)

» Max. Capacity Stainless Steel: 18 ga (1.25 mm)

Model D600

The 21 ft. version Evobend® stands out with its unique price/performance ratio. With this machine you will work faster and more efficiently than with comparable machines. Metal building contractors, roofers, facade builders and many other sheet metal fabricators look forward to a long-folding machine of this exceptional quality.

Specifications:

» Folding Length: 252 in (6400 mm)

» Backgauge Depth: 49 in (1250 mm)

» Number of Legs: 8

» Total Length: 307 in (7800 mm)

» Total Depth: 71 in (1880 mm)

» Total Height: 74 in (1875 mm)

» Max. Capacity Mild Steel: 14 ga (2 mm)

» Max. Capacity Aluminum: 1/8 in (3 mm)

» Max. Capacity Stainless Steel: 18 ga (1.25 mm)

Model D800

The 26.5 ft version Evobend is capable of processing numerous quantities of material in less time. This high-end folding machine has been specifically developed for large edging companies producing tapered parts for wall cladding as an example.

Specifications:

» Folding Length: 317 in (8054 mm)

» Backgauge Depth: 49 in (1250 mm)

» Number of Legs: 10

» Total Length: 372 in (9454 mm)

» Total Depth: 71 in (1880 mm)

» Total Height: 74 in (1875 mm)

» Max. Capacity Mild Steel: 14 ga (2 mm)

» Max. Capacity Aluminum: 1/8 in (3 mm)

» Max. Capacity Stainless Steel: 18 ga (1.25 mm)

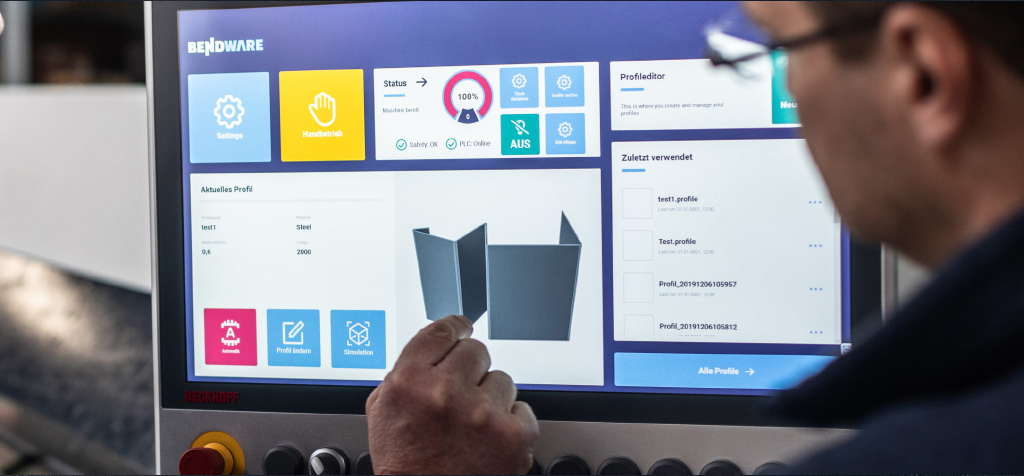

INNOVATIVE SOFTWARE

Unlike existing control systems on the market, the newly developed Evobend software stands above the rest with unrivaled usability. The easy-to-use controls are so simple that even novice operators will quickly and comfortably grasp it. The clear and intuitive design is the result of years of in-depth software experience and development. A machine only operates as well as its user, which is why particular attention was put into developing the Evobends controls.

SUSTAINABLE DRIVE TECHNOLOGY

The revolutionary all-electric drive system clearly distinguishes the Evobend® from traditional machines on the market. The use of electric motors in all processes leads to a more profitable cost/benefit ratio over time. The combination of linear technology with servo motors completely replaces previous hydraulic drives. The significantly improved power consumption not only reduce electricity bills, but also keep maintenance costs to a minimum. With Evobend you’ll work sustainably and actively against environmental degradation. Your employees will enjoy the reduced noise pollution, which leads to improved morale and increased productivity.

UNIQUE BENDING-PRINCIPLE

In addition to energy savings, the patented technology of the Evobend® offers further significant advantages in the bending process: Highly precise bends with unique 300° bending clearance make the Evobend® the most versatile long folding machine on the market. An individual bending curve is calculated for each task – depending on material type and thickness – and thus the correct rolling of the bending tool is prepared, therefore consistent results of the highest standard can be achieved.

SPACE SAVING SAFETY ENGINEERING

Every user knows all too well how much space is taken up by existing safety fences. Better use of space not only saves money, but also gives the operator better peace-of-mind. The Evobends optional automatically retractable safety fences extend when the machine is in operation. If the machine is not in operating, the fences will stay in their resting position until they are needed. Manually retractable comes standard on a machine. The fences are thus protected against damage caused by forklifts and more. This saves valuable space at a time when space costs are rising.