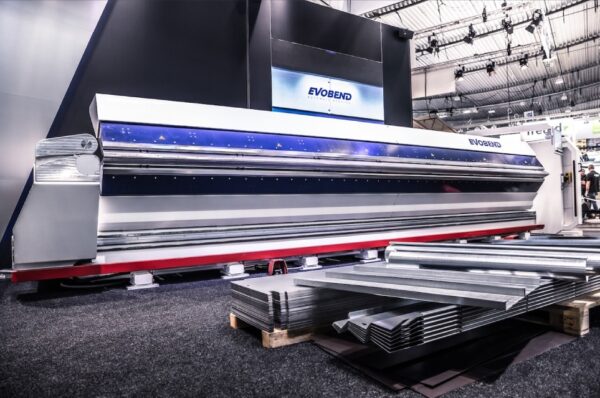

In the dynamic and competitive world of sheet metal bending, the EvoBend has emerged as a clear frontrunner. This article delves into the specific characteristics that elevate the EvoBend above its competitors, highlighting its precision, efficiency, versatility, user-centric design, space efficiency, and the economic advantages it brings to businesses.

Precision and Efficiency

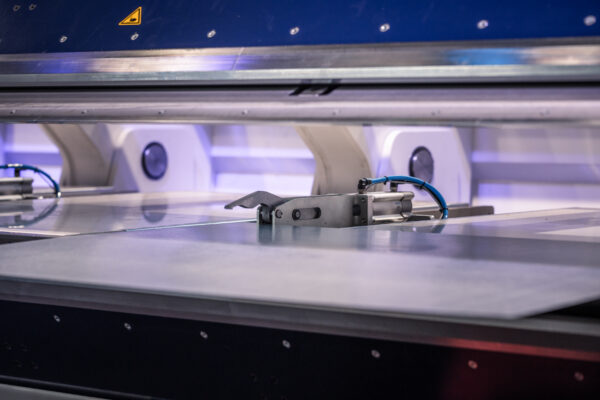

One of the foundational attributes of EvoBend is its unparalleled precision. The patented bending technology ensures that each bend is executed with an extraordinary degree of accuracy. This precision translates into fewer errors and thus, less waste and rework. But precision alone isn't what makes the EvoBend stand out. Its unique tooling allows for the hemming process to be integrated into the bending, turning what was traditionally a two-stage process into a more streamlined single-pass operation. This fusion of precision and efficiency is a testament to EvoBend's innovative design.

Electric and Energy-Efficient Design

The decision to power the EvoBend with servo motors and make it fully electric is not just an innovative choice but a forward-thinking one. Hydraulic systems, while prevalent in the industry, come with a set of challenges – fluid leaks, pressure inconsistencies, and regular maintenance. EvoBend sidesteps all these issues, offering a cleaner, more reliable operation. Furthermore, the absence of hydraulic pumps inherently leads to a massive reduction in energy consumption. In an era where sustainability and eco-friendliness are paramount, the EvoBend’s energy-efficient design positions it as a responsible choice for modern businesses.

Versatility is the bedrock of innovation

The EvoBend, with its impressive 300° bending range, shatters the limitations posed by conventional machines. This capability ensures that designers and engineers are free to innovate, unshackled by machine constraints. Such flexibility in bending ensures that the EvoBend is the machine of choice for complex projects requiring intricate profiles and shapes.

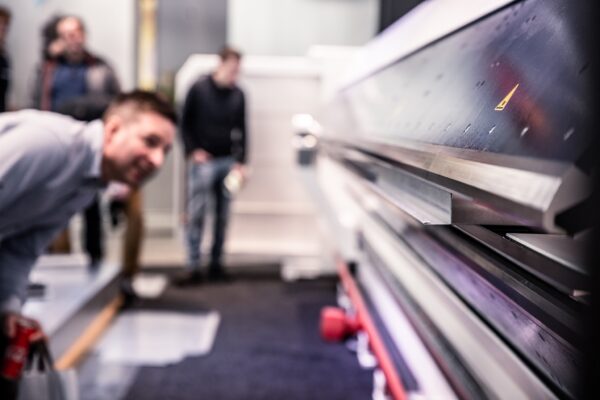

Operator-Centric Design

In any manufacturing setup, the operator is a pivotal figure. Recognizing this, the EvoBend has been meticulously designed to prioritize operator comfort and safety. By reducing the manual force required and simplifying the insertion process, it ensures that operators remain productive and less fatigued. Furthermore, an array of safety features—from light curtains to laser scanners—ensures that the workspace is incident-free.

Economic and Long-Term Benefits

All the aforementioned attributes of the EvoBend culminate in significant economic advantages for businesses. With reduced waste, minimal errors, decreased energy consumption, and limited maintenance, operational costs are kept at bay. This makes the EvoBend not just an equipment acquisition but a strategic investment promising strong returns.

In conclusion, the EvoBend represents the zenith of sheet metal bending technology. Its blend of precision, efficiency, versatility, operator-centric features, and economic benefits positions it as an indispensable asset for businesses aiming for excellence in their operations.