Changing The Shape Of Metal

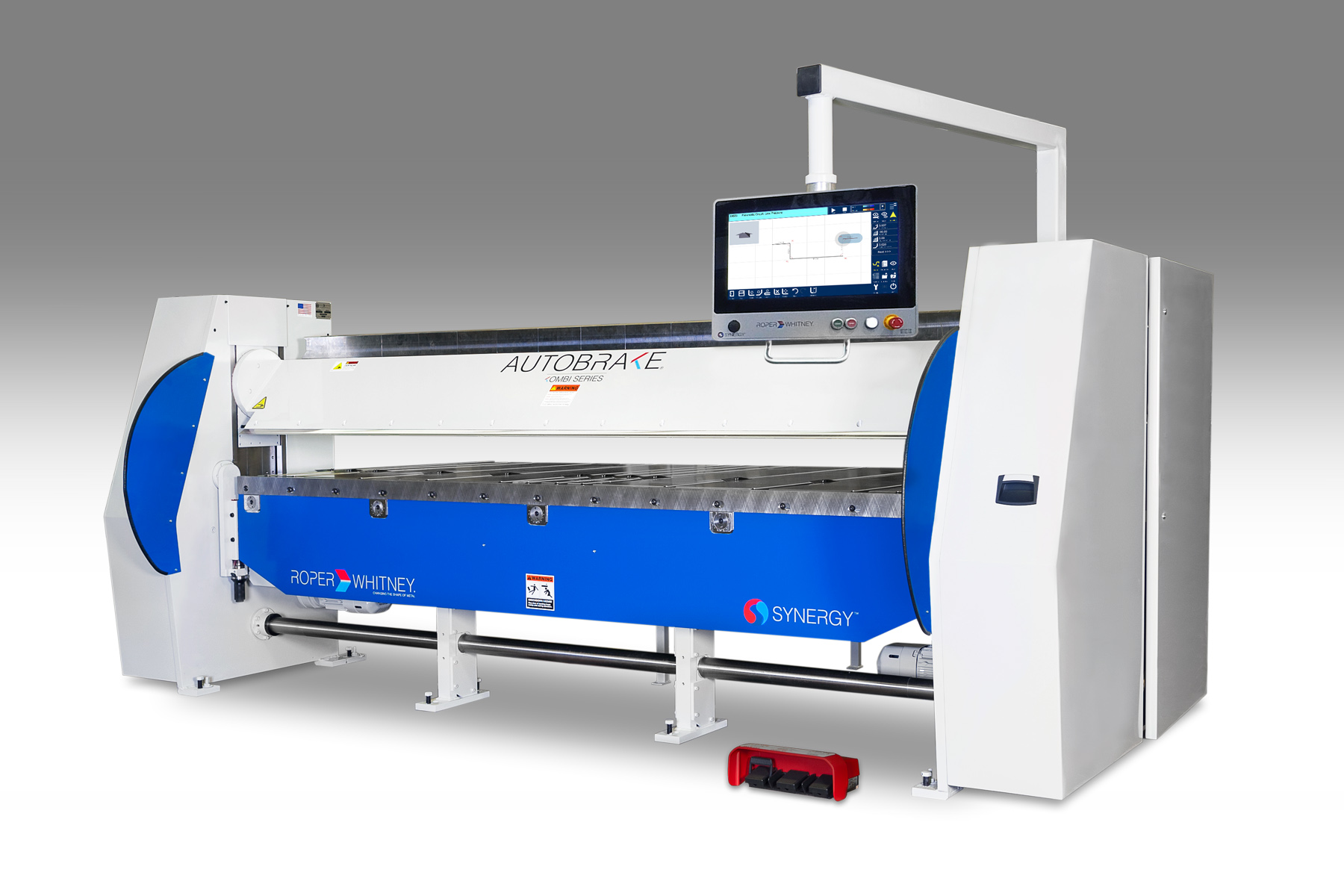

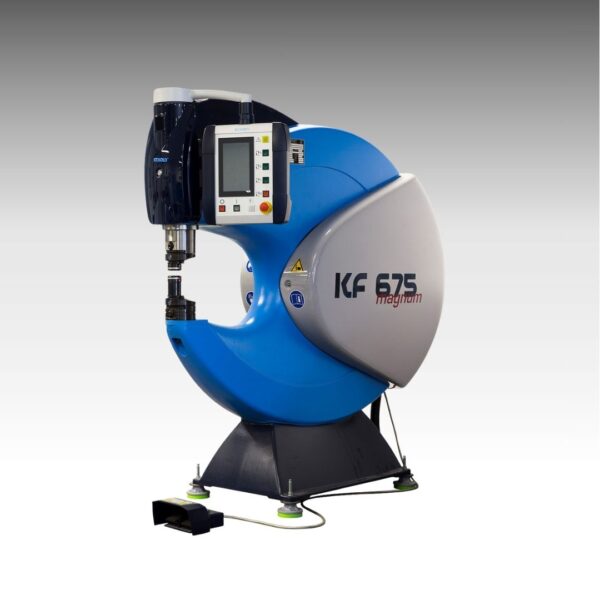

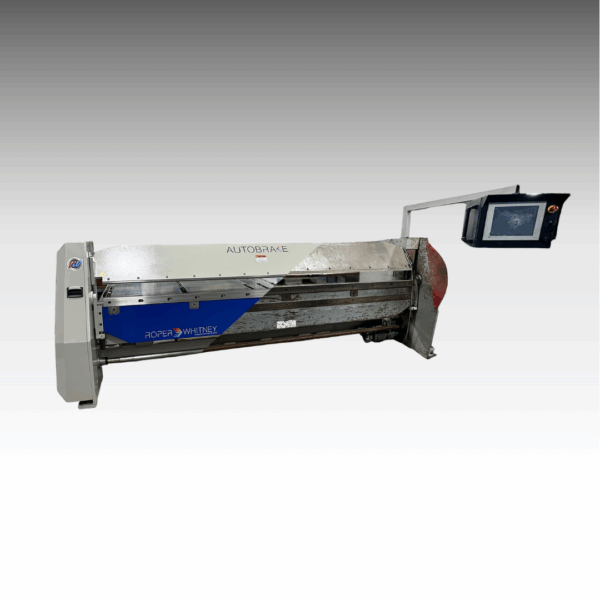

Since 1910, Roper Whitney has been producing high-quality tools and sheet metal fabrication equipment that change the shape of sheet metal, literally, from a simple punch to folding shapes with complex geometries. Over the decades, Roper Whitney has become a household name in sheet metal forming shops, most notably with American-made AutoBrake® sheet metal brakes as well as brands like Pexto® and Connecticut®.

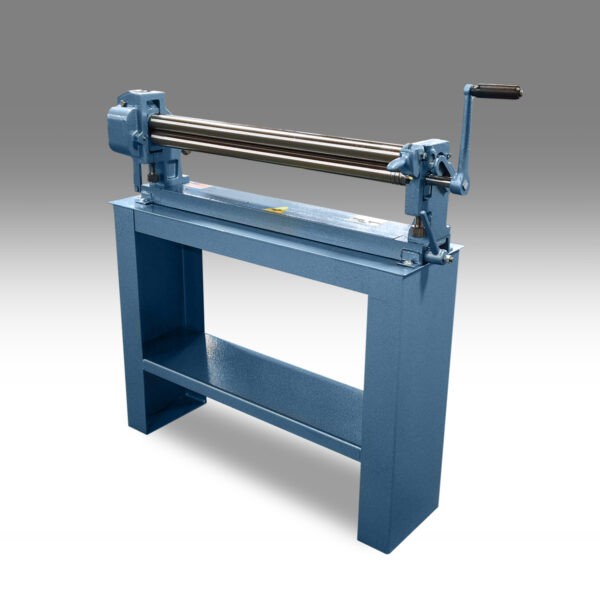

With the release of powered long folders, Roper Whitney has one of the most comprehensive product line-ups for bending, folding, forming, notching, punching and shearing – designed to streamline the sheet metal fabrication process.

Sheet metal brakes are powered by the SYNERGY control system that manages all machine motions with an intuitive interface and real-time bending sequences. SYNERGY also provides easy management of projects and product drawings.

Product Categories

Featured Product

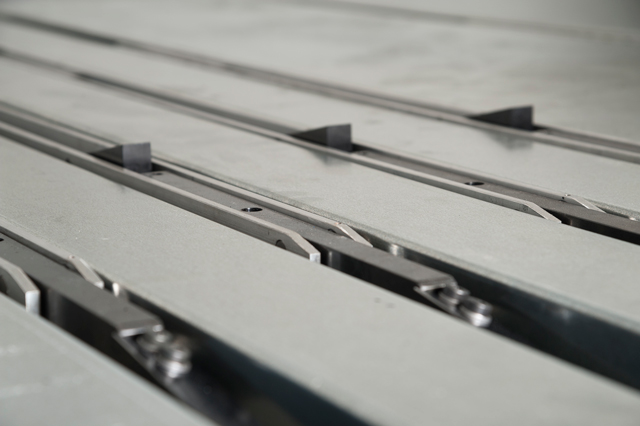

AutoKut 160

The ultimate coil processor, the AutoKut 160, is built for heavy-duty work and high-speed performance, maximizing efficiency all in one compact machine. Equipped with automatic controls and an easy-to-use operator interface, the 160 streamlines and simplifies coil processing. It does not require disassembly for blade changes unlike other machines on the market, and is designed for long-term serviceability with all mechanisms outside the machine.