Pioneering Automotive and Aerospace Solutions through Partnership with Eckold

The automotive and aerospace industries demand cutting-edge technology, precision engineering, and innovative manufacturing solutions. Roper Whitney, in partnership with Eckold, is at the forefront of providing advanced sheet metal fabrication equipment and services to meet the unique requirements of these sectors.

By joining forces, Roper Whitney and Eckold are transforming the automotive and aerospace industries with their advanced sheet metal fabrication solutions. Their cutting-edge machinery and technologies deliver the precision and efficiency necessary to remain competitive in these rapidly evolving sectors. By choosing Roper Whitney and Eckold, you can trust in your ability to produce top-quality components and exceed industry expectations.

Roper Whitney and Eckold provide a wide array of machinery and technologies designed to cater to the automotive and aerospace sectors, including:

Clinching and Joining Systems

Eckold’s innovative solutions for sheet metal joining and assembly, ideal for the fabrication of lightweight and strong components in automotive and aerospace applications.

Shaping and stretching Technologies

Advanced machinery for forming and shaping sheet metal, providing the flexibility and precision required for producing automotive and aerospace components.

Eckold GL 2 Handheld Planishing Hammer

The Eckold GL2 handheld planishing hammer is the perfect tool for smoothing, stretching, curving, or straightening sheet metal. Fine weld seams can be planished fast and efficiently using the GL 2. Easily change from die to die with the quick-release mechanism. They’re simple and high quality thus the choice for industry leaders such as automobile and aircraft restoration, custom motorcycle builders, race car fabrication and more.

The Eckold GL2 handheld planishing hammer is the perfect tool for smoothing, stretching, curving, or straightening sheet metal. Fine weld seams can be planished fast and efficiently using the GL 2. Easily change from die to die with the quick-release mechanism. They’re simple and high quality thus the choice for industry leaders such as automobile and aircraft restoration, custom motorcycle builders, race car fabrication and more.

Eckold HZ 52 Handheld Shrinker Stretcher

This handheld shrinker stretcher is ideal for adjusting, correcting and touch-up jobs while on the worksite. They can handle mild steel profiles up to 1.0 mm/20 gauge thickness or aluminum up to 1.5 mm/16 gauge thickness.

This handheld shrinker stretcher is ideal for adjusting, correcting and touch-up jobs while on the worksite. They can handle mild steel profiles up to 1.0 mm/20 gauge thickness or aluminum up to 1.5 mm/16 gauge thickness.

Eckold Kraftformer KF 800

The Eckold Kraftformer KF 800 is air powered and controlled by a foot pedal, and you can easily switch between single stroke and continuous stroke operation. The single stroke mode combined with the machines massive reach is extremely beneficial for correction jobs. The machine has 2 different stroke settings depending on your forming force requirements.

The Eckold Kraftformer KF 800 is air powered and controlled by a foot pedal, and you can easily switch between single stroke and continuous stroke operation. The single stroke mode combined with the machines massive reach is extremely beneficial for correction jobs. The machine has 2 different stroke settings depending on your forming force requirements.

A digital display shows the machines ram position with 0.1 mm precision which results in accurate repeatability of the forming force. The KF 800’s adjustable height allows for an ergonomic working position for the operator. The Eckold Kraftformer KF 800 uses the same tooling as Eckold’s popular KF 170 PD allowing for easy tool changes within seconds. The range of tools covers shrinking, stretching (both steel and non-marring synthetic inserts), doming and planishing operations. Like the other Kraftformer models, the all-new KF 800 is durable, versatile and precisely engineered with every detail in mind.

View Tooling Catalog *The KF 800 uses the same tooling as Eckolds popular KF 170 PD allowing for easy tool changes within seconds.

Eckold MCD 30/50 AH Portable Clinching Unit

Eckold MCD 30/50 AH portable clinching unit is an innovative, proven tool for the joining of sheet metal and profiles. Work pieces are permanently joined by cold forming – doing away with fixtures and auxiliary parts. The primary advantage of clinching is the fact that a positive joint can be formed directly from the sheet metal material. The technique is also suitable for the joining of work pieces of different materials and thicknesses.

Eckold MCD 30/50 AH portable clinching unit is an innovative, proven tool for the joining of sheet metal and profiles. Work pieces are permanently joined by cold forming – doing away with fixtures and auxiliary parts. The primary advantage of clinching is the fact that a positive joint can be formed directly from the sheet metal material. The technique is also suitable for the joining of work pieces of different materials and thicknesses.

Eckold MZD 45/35 P Portable Clinching Unit

Eckold MZD 45/35 P portable clinching unit is an innovative, proven tool for the joining of sheet metal and profiles. Work pieces are permanently joined by cold forming – doing away with fixtures and auxiliary parts. The primary advantage of clinching is the fact that a positive joint can be formed directly from the sheet metal material. The technique is also suitable for the joining of work pieces of different materials and thicknesses.

Eckold Handformer HF 100

The Eckold Handformer HF 100 is a hand powered shrinker/stretcher that replaces the laborious hammer work when forming sheet metal. It is suitable for shrinking and stretching mild steel sections and profiles up to a thickness of 16 gauge, or up to 14 gauge aluminum. The HF 100 is a stationary machine for craftsmen enterprises with a reach of 4″ (100 mm). Tools for punching, notching and edging are available in addition to standard forming tools.

The Eckold Handformer HF 100 is a hand powered shrinker/stretcher that replaces the laborious hammer work when forming sheet metal. It is suitable for shrinking and stretching mild steel sections and profiles up to a thickness of 16 gauge, or up to 14 gauge aluminum. The HF 100 is a stationary machine for craftsmen enterprises with a reach of 4″ (100 mm). Tools for punching, notching and edging are available in addition to standard forming tools.

Eckold Kraftformer KF 170 PD

The air powered KF 170 PD is the smallest of the Kraftformer machines. It can be switched between single and continuous stroke thus is ideal for correcting and adjusting jobs, and can also be used for punching, notching and clinching. With a horizontal throat of 6.7″ (170 mm), the KF 170 PD is capable of working large components up to 14 gauge (.08″ /2 mm) material thickness.

The air powered KF 170 PD is the smallest of the Kraftformer machines. It can be switched between single and continuous stroke thus is ideal for correcting and adjusting jobs, and can also be used for punching, notching and clinching. With a horizontal throat of 6.7″ (170 mm), the KF 170 PD is capable of working large components up to 14 gauge (.08″ /2 mm) material thickness.

Eckold Handformer HF 100 PA

The Eckold Handformer HF 100 PA is an air powered shrinker/stretcher that replaces the laborious hammer work when forming sheet metal. With this machine you have both hands on the job for easy and precise holding and guiding of work pieces while releasing strokes and adjusting pressure with the foot-pedal switch. Quite an advantage when handling large and bulky parts.

The Eckold Handformer HF 100 PA is an air powered shrinker/stretcher that replaces the laborious hammer work when forming sheet metal. With this machine you have both hands on the job for easy and precise holding and guiding of work pieces while releasing strokes and adjusting pressure with the foot-pedal switch. Quite an advantage when handling large and bulky parts.

The air powered HF 100 PA has a built in pressure relief valve to avoid overloading tools. Each step on the foot pedal releases one working stroke. Pressing down the foot pedal switch lightly releases a stroke with limited pressure. If you want the full power of the machine applied you simply press the pedal down all the way.

Eckold Kraftformer KF 324

The KF 324 is one of the medium-sized machines from Eckold. It combines strength and durability with power, precision control and is characterized by a modern design. The control system display visualizes operations, fault tracing and maintenance rates thus ensuring optimum machine performance. All forming tools have a quick change design which eliminates down time. Because of the smaller size and wide range of tools, the KF 324 is the perfect all-rounder for any shop. With a horizontal throat of 13.4″ (340 mm), the KF 324 is capable of working large components up to 14 gauge material thickness.

The KF 324 is one of the medium-sized machines from Eckold. It combines strength and durability with power, precision control and is characterized by a modern design. The control system display visualizes operations, fault tracing and maintenance rates thus ensuring optimum machine performance. All forming tools have a quick change design which eliminates down time. Because of the smaller size and wide range of tools, the KF 324 is the perfect all-rounder for any shop. With a horizontal throat of 13.4″ (340 mm), the KF 324 is capable of working large components up to 14 gauge material thickness.

Eckold Kraftformer KF 340

The Eckold KF 340 is a robust, medium-sized Kraftformer that brings advanced versatility and precision to metal forming workshops. This model stands out with its ability to adjust the working stroke and speed dynamically, thanks to a sophisticated gear motor for the upper ram adjustment and a potentiometer coupled with a foot pedal for speed control. Capable of handling material thicknesses up to 11 ga. (mild steel), the KF 340 is designed to cater to a wide range of metalworking tasks including shrinking, stretching, doming, and planishing. Its extensive tool compatibility and adjustable features make it an essential all-rounder for precision metal forming.

The Eckold KF 340 is a robust, medium-sized Kraftformer that brings advanced versatility and precision to metal forming workshops. This model stands out with its ability to adjust the working stroke and speed dynamically, thanks to a sophisticated gear motor for the upper ram adjustment and a potentiometer coupled with a foot pedal for speed control. Capable of handling material thicknesses up to 11 ga. (mild steel), the KF 340 is designed to cater to a wide range of metalworking tasks including shrinking, stretching, doming, and planishing. Its extensive tool compatibility and adjustable features make it an essential all-rounder for precision metal forming.

Eckold Kraftformer KF 470

The KF 470 is the second largest machine in the Kraftformer range. It combines sturdiness and durability with power, precision control and is characterized by a modern design. The control system display visualizes operations, fault tracing and maintenance rates thus ensuring optimum machine performance. All forming tools have a quick change design which eliminates down time. The combination of sturdiness, strength and precision makes this machine the favorite among industrial construction professionals worldwide. With a horizontal throat of 18″ (470 mm), the KF 470 is capable of working large components up to 9 gauge (.16″ / 4 mm) material thickness.

The KF 470 is the second largest machine in the Kraftformer range. It combines sturdiness and durability with power, precision control and is characterized by a modern design. The control system display visualizes operations, fault tracing and maintenance rates thus ensuring optimum machine performance. All forming tools have a quick change design which eliminates down time. The combination of sturdiness, strength and precision makes this machine the favorite among industrial construction professionals worldwide. With a horizontal throat of 18″ (470 mm), the KF 470 is capable of working large components up to 9 gauge (.16″ / 4 mm) material thickness.

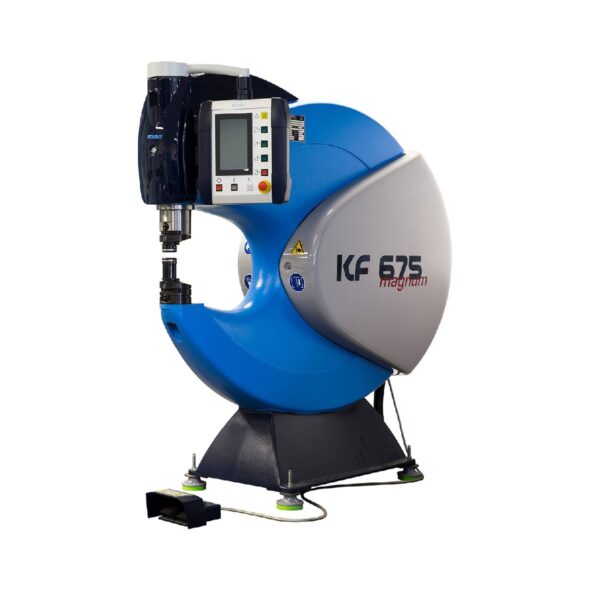

Eckold Kraftformer KF 675

The Eckold Kraftformer KF 675 is the biggest of the KF series machines. Features include the precise control and adjustable stroke speed, repeat accuracy, up to 25 stored programmable processes and more. With a horizontal throat depth of 26.5″ (675mm) the KF 675 can easily handle very large and thick materials up to 7 gauge (.25″ / 6mm) material thickness.

The Eckold Kraftformer KF 675 is the biggest of the KF series machines. Features include the precise control and adjustable stroke speed, repeat accuracy, up to 25 stored programmable processes and more. With a horizontal throat depth of 26.5″ (675mm) the KF 675 can easily handle very large and thick materials up to 7 gauge (.25″ / 6mm) material thickness.